As the name implies, low voltage high current DC power supplies delivers high current output at low voltage to a load. In general, low voltage high current DC power supplies are designed for industrial testing and power electronics development. Output voltage is normally below 60V, typically 5V 10V 15V, and output current is always 500 amps or higher.

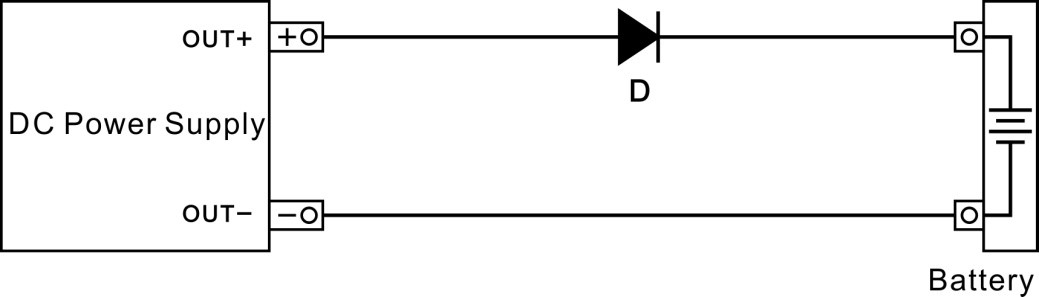

As the electronic industry grows, so dose demands for high power density, high current capacity, precise control and output. Low voltage high current DC power supplies are essential in a wide range of applications in modern industry, such as battery charging, motor testing, electric vehicles components and systems testing, powering electrolysis systems, etc.

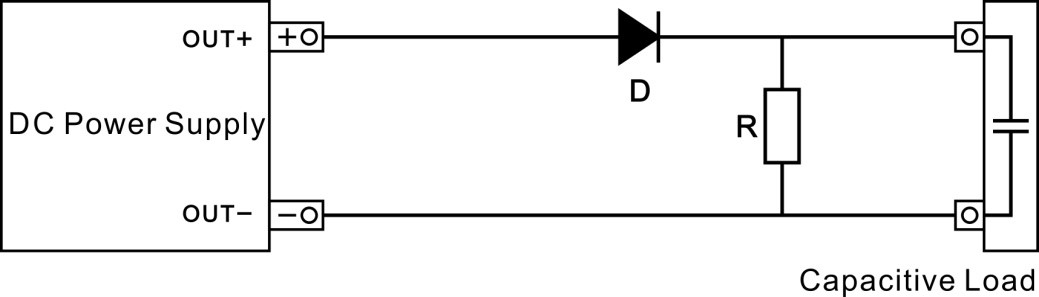

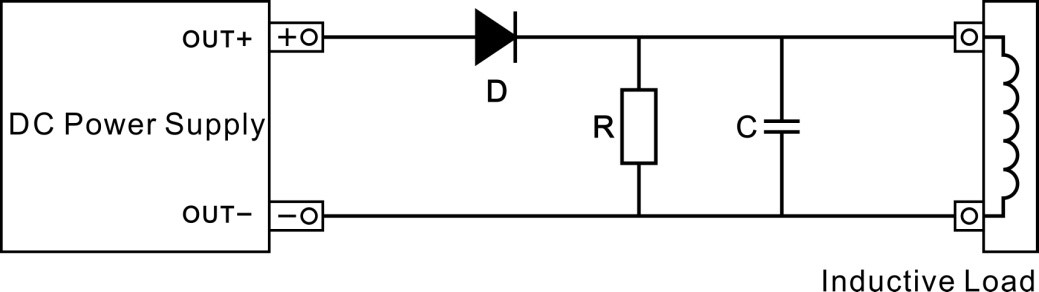

TWINTEX PCL series low voltage high current switch mode DC power supplies adopts PWM technology, which greatly reduces switching consumption and therefore facilitates switching function with high efficiency and high stability. These high current DC power supplies provide high current output with good stability for applications listed below.